Cow Patty News

Monthly Newsletter

June 2002

The Anniston RC Flyers & Talladega Radio Control Club

God Bless Amereica

What is in the news letter this month?

|

Gas engines built for RC compared to production line gas engines

By James Goss

It is a well-known fact that you can buy an engine such as a weed-eater or chainsaw engine at a much cheaper price than you can a gas engine built for the RC hobby. Of course you will have to convert the engine for RC use before you can put it in your plane. The question is, “Are they as good as the RC built engines”? When I say as good I mean do they have the same horsepower to weight ratio and do they produce compatible RPM ratings? Above all will they last for any length of time? I don't think there is any doubt that a gas engine built specifically for RC will out perform a production line engine, but are they worth the extra cost? If you want a high performance gas engine it is going to cost you for all the extras. The high performance RC engine will have a special built crankcase that weighs less and comes with precision bearings and seals. They also have special build cylinders in most cases. For a 2.4 cubic inch engine we are talking about less than $200 for the production line engine and as much as $600 for the RC built engine. Have you ever wondered just what they put into those RC gas engines that make them cost so much more than a weed eater engine? In trying to answer these questions I have contacted most of the RC gas engine manufactures so they could tell us first hand why their engines cost so much more that a production line gas engine. Here are some of their replies:

# 1.

From: [email protected] (Bill Oberdieck)

There is no comparison. This picture shows our 2.6 which is .4 cubic inches larger than a G38 but it is 1-1/4 lbs lighter and puts out about 50% more power. We use precision bearings, seals and other components not used in production engines. Another factor is our engines are hand crafted one at a time compared to the production engines made in 1000 pieces. Anybody interested should just get the cost of these parts to convert.

#2

From: [email protected] (Ralph)

Hello James

All engines use chainsaw or weed eater pistons, cylinders, and carburetors.

Some of the manufactured engines use the chainsaw crankshafts, a few make their own. All manufactured engines use some form of electronic ignition. Zenoah and a few others, Fuji, U S, small Quadra, and Mac Minarelli use flywheel magneto ignition, which is heavier, so the manufactured engines claim less weight. A converted chain saw or weed eater with CD ignition weighs very little more than one of the high priced engines, and will run just as well. A few examples...

Zenoah G62 with CD ignition, made from a Red Max chainsaw, weighs about 4 lbs.

A Poulan 2.6 chainsaw engine, converted, weighs about 3 lbs. A Poulan 2.6 costs about $100.00 from Lawnstation.com...Conversion costs vary, but for about $300.00 it's a good alternative to a BME 44 or Brison or Fox 2.4 for $500.00 or more...

Bottom line. Manufacturers like to think their engines are superior, but

It's mostly advertising. RC

#3

From: [email protected] (Kurt Roth)

Hi James

I don't have time for a long detailed message right now, but I can give you an overview. We manufacture the crankcase, connecting rod, crankshaft, back plate, motor mount, carb spacer, and muffler. Just in CNC machine time (mill and lathe) your looking at about 2 1/2 hours per engine. Most machine shops charge 1 dollar per minute plus material. The reason for making all the parts is for better quality, lighter weight and more performance. The electronic C&H syncro spark ignition retails at $134.00. The cylinder and piston assemblies range from $150.00 to $225.00, and carbs retail at $35.00 to $45.00. As you can see, a lot of time and money is invested for our engines, and are not just weed eater conversions. I hope this will help you with you comparison.

Thank You

Kurt Roth

#4

From: [email protected] (Hobby Services)

Dear James:

Thanks for the interest. Your Email was forwarded to us because we are the service center for Mac Minarelli, US Engines, and Fuji engines. All of these, of course, are purpose-built engines for R/C use.

While we don't have a lot of specific information, the main reason the specific R/C engines cost more than, say, an Echo weed-whacker engine is due to the numbers sold. Thousands and thousands of identical small engines are built to be specifically installed in small power tools, weed-whackers, chainsaws, and the like. Maybe a thousand or two of the R/C engines of all types are sold. Lower volume means higher prices.

Because the small power tool engines are all exactly alike, they can be built on high-speed assembly lines. Model engines need to be modified from the power-tool type. They don't need the big, heavy pull-starter, and they don't need the cooling shroud. Along with this, the flywheel doesn't need all of the fins to move air that the power-tool engine needs. That doesn't include adding a specialized prop driver. The extra steps also add to costs.

Eventually, when you get down to it, there are a lot of differences between the power-tool engine and the R/C engine. Just talk to anyone who's converted an inexpensive weed-whacker engine to R/C use. While it may seem to cost less than the model engine, the modeler didn't account for the cost of his labor or the amount of profit a manufacturer has to make just to stay in business, let alone grow the business. Add in markups for distributors and retailers, and you can easily see why the engine for R/C use costs what it does.

Like everyone else, we'd like to see model engines cost less, but to do that, many, many more engines would have to be sold. The only way to do that is to grow the hobby. If a few hundred thousand engines could be sold, then prices would come down...or at least not increase as fast.

Sincerely,

Bill Baxter, Manager

Hobby Services

#5

From: DHCHIPMUNK

James

I am a little tight on time I work two jobs Jag being one of them. Give my web sight a good look there is a lot of information in there. I can tell you this most of the gas engines out there were designed to be industrial engines. Zenoah was sold in the Green machine. This is a professional garden tool weed wacker, hedge trimmer, chain saw, exc. The Quadra is a Canadian chain saw engine.

I forwarded your letter to Dan Egelhoff he will probably add to this.

#6

From: TEAMERICA

James,

I was forwarded your letter from Dale at JAG Engines.

I would love to read your newsletter article when you finish it. I believe you will get a lot of responses with material for you to use. Your request is both friendly and informative enough that I know what you are looking for and think I can help.

My parents were brought together by model airplanes. My Dad married his Flying Buddy's sister. Caster and Nitro run in my veins and RF has been frying my brain for over 40 years. I have flown just about every kind of R/C aircraft there is and usually end up competing with them. I have always dreamed of making a living from my hobby and occasionally have done that for short periods. It more practical to hope for offsetting some of the expenses. When I die, my son will be left with only the flying skills I taught him and a garage full of airplanes. The reason I put it this way, is because you are asking about the difference between the "company" engine builder and the "do-it-yourselfer" engine converter. Companies that have large investments in machines and tooling need to make a reasonable return on their investment. "Cottage" machinists usually got there because of an interest, if not love, for the hobby. Many are retired from other industries such as Aeronautical Engineering, Electronics or Machining. JAG Engines is one such business. It was started by a retired engineer and now owned and operated by a hard worker in the Aeronautical industry that uses and enjoys what he makes. He also derives a continued satisfaction with meeting and staying in touch with others that not only enjoy his hobby, but enjoy doing a little more for themselves in order to save a buck. You might notice that the JAG Engines website shows many applications of the Ryobi engine conversion on airplanes that I would consider "major projects". These are craftsmen. Not including the Ultra Stick (ARF). That was my idea. I did it because I couldn't get that Magnum 1.80 to run. But, for the most part, these testimonials are from people that are not just "users" but modelers. Not just "flyers" but craftsmen that know what's inside and why.

I have nothing against large engine manufacturers. I own 4 Quadras, 4 Zenoahs, a Sachs, a dozen OS and a few Magnum 4-strokes. The ones I enjoy flying most are the gas engines. Why? Well, I have wiped off more grease from the two stroke glow engines than I care to estimate. I suspect it is enough to float me if not a battleship. I don't trust glow plugs and don't like the cost of Nitro and Methanol. Everything has it's purpose and I do enjoy our AT-6 racing class with the O.S. . 46FX engines. So I endure the greasy cleanup. The fuel is Free with the race entry.

But back to the Large engine manufacturer Vs Small engine converters. Many people don't have the time, skills or tools to do an engine conversion themselves. Many like the implied reliability and convenience that comes from a "Factory" built engine. Most kits and plans actually show drawings of common manufactured engines and how to install them in that particular plane. Partly because of availability and partly due to a perceived consistency or predictability of the common manufactured engines. I can remember when I was so anxious to get the construction done and get flying that I didn't have time to learn another discipline such as Mechanics and Engines. I was that way when I first started flying Giant Scale back in the early 90s. Since then, the Ignition timing is no longer a mystery and the spark plug is my friend.

For me, it all comes down to the right engine for the purpose. You won't likely see a Ryobi conversion at the TOC. You will, however find many Factory built engines that have been personally massaged for that event. That is no secret but it all adds to the cost of doing business when you are in the fast lane. Ask them about their engine and you will get little more than the company name. Go to a Fun fly or IMAA event and you will very likely find a well crafted model with a hand converted engine that shows just as much pride on the owner's face as the rib stitching. Ask them about their engine and you will get a story, a recommendation, a few part numbers and a smile.

There is your story. JAG Engines has enabled me to learn more about my Ryobi and save a bunch of money. There is my recommendation JAG

#7

From: [email protected] (Dave Reid)

Hello Jim-

I'll do my best to answer your questions.

In the scope of things, we modelers are not a very big lot when it comes

to quantities for manufacturing. Compared to weed wackers, chainsaws and

other similar items, the amount of engines we require is very small. Take

for example the weed whackers. Most of the time they are sold at cost or

slightly above in any of a number of home centers and discount stores. Most

of them will have a very large display of units to sell. Most of the big

retailers have anywhere from 1500 stores to over 3000. If each store placed

an order for only 24 units, (most of the orders are in the hundreds). that

would be a total of 36000 to 72000 units per chain. And remember, the units

were made to cut grass, not fly planes which is considered dangerous by some

of the insurance underwriters.

When we make the engines for modeling use, almost all use parts from the

lawn and garden industry, but we don't buy complete weedwackers or

chainsaws. We buy parts, which are sold to the model engine maker at higher

margins than complete weedwackers. You have bought parts for your car. Can

you imagine building your new car from parts? I think not!

When you get some garage modeler converting weedwackers, he is not

paying liability insurance, little to no advertising, no warranty work, and

his profit motive is just some extra pin money he can spend on the hobby.

We on the other hand spend thousands for advertising, an obscene amount

on liability insurance in case some klutz sticks a hand in the engine or

crashes into something. After all, the modeler will take no responsibility

for his actions and his attorney just sees dollar signs in a law suit.

We are also expected to warranty the engine forever from everything from

a bad spark plug, (which we have no control over), to crashes caused by

trying to get the last rpm from the engine or not using the correct gas and

oil mix because his buddy said that "no one uses that kind of oil".

Lastly, we manufactures do not do this just for something to do. We like

to make a reasonable profit, and if we do make a profit, before we can spend

any of it, we have to pay bills and the IRS. Also, like with other

consumables on the market, everyone wants to pay next to nothing for it, but

all want to work for 25 dollars an hour or more plus benefits.

I hope this is interesting reading to you. Most modelers have no concept

on the expense of doing business, and the less they know the more they

complain about pricing.

Regards-

Dave Reid

http://www.reidsmodels.com

|

Who Is Your Copilot?

By James Goss

I have always said we should have a copilot at our side when we are flying a radio-controlled plane. This copilot should be able to fly and land the type plane you are flying at the time, be it giant scale or small scale. You should have confidence in your copilot and not hesitate to hand him your radio if you feel the need to do so. Some R/C pilots may feel embarrassed if they had to hand over their radio and let someone else fly and land their plane for them, not me. If you are having trouble flying, and that can be any number of things, just think about the consequences of not having someone to help. With a copilot at your side you are not only assured of having backup for emergencies, but he can also be your spotter. A spotter can keep an eye on all the other planes for you while they are taking off or landing and inform you that you are about to get hit by an out of control plane. (You might want to move). I know of several times in the past that I have had to ask someone to fly my plane while I needed to do something such as:

Go get my sunglasses

Find my cap

Get fire ants off my feet

Trying to stop my eyes from watering (crying)

Recover from a twisted ankle

Removing a gnat from my eye ( those pesky devils)

Warm my frozen hands

Sun blinded

A lot more serious things than I have listed above could happen to any of us during a flight. We don't think about having a sudden physical or health problem because we are having too much fun at the field, but it is always a possibility. The larger the plane is the more you need a copilot. A small plane can do a lot of damage if it hits someone or some property, but a 20 or 30 pound plane can really do some damage. I make it a practice to never fly giant scale planes without a copilot at my side that is capable of landing my plane if something happens to me. I just feel more relaxed while flying the big birds if I know I have a backup pilot close by. The giant scale planes are a little different from the smaller planes. They fly about the same while in the air, but when it comes to landing it is a whole new ball game. The new aerobatic giant scale planes tend to drop out of the sky in a hurry when you chop the power and some of them needs to come in a little hot to prevent a stall. It only takes one bounce off the ground and then a stall and you have lost a $50 dollar prop, bent landing gear and maybe some serious damage. When these big birds come down in the wrong position my wallet begins to quiver. This is why your copilot needs to be experienced in flying giant scale planes or any other type you are flying. Why take a chance on loosing your plane, have a backup copilot.

Let me give you an example of what I am talking about. I am sure the person that this happened to will not mind if I tell this incredible but true story. A few months back at the Eastaboga flying field, Pat Thomas was having his regular eventful day while flying his large Cap-232. When Pat arrives at the field everything begins to liven up because Pat is just that type of fellow. He likes to joke around with all the other members and everybody that knows Pat really likes him. Pat is an excellent R/C pilot and has been in the sport for many years. At this time he likes to fly large sport aerobatic planes and like me he loves to hover his planes. I wasn't at the field the day this happened but was told the story later by Pat. Here it is: Pat was in his first or second flight of the day and noticed he had to blink his eyes. This was not unusual for Pat because Pat wears contact lens and everybody that wears them knows that you have to blink quite often to keep your eyes from drying out. All of a sudden Pat noticed he could not see his plane with the clarity that he was accustom to. He then realized that one of his contacts had popped out of his eye when he blinked. Now what would you do in a case like this? Pat made the decision to close the eye that had lost the contact and fly with just one eye. When you close one eye your depth perception immediately becomes mislead and it is hard to make the right decision about where you are in respect to other objects. Amazingly Pat made a good landing and when he looked down to his transmitter he found the contact lens that had popped out, it landed on his radio. That was really good luck for Pat to find his contact lens and also to have a good landing with only one eye. Pat, a drop of ca would keep that from happening again.

The above example turned out to not be serious, but the possibility of a serious accident was lurking close by. If it had of happened to someone with less experience than Pat, they might have panicked and the plane might have developed a mind of its own and became a deadly weapon. There are so many things we don't think about that it scares the heck out of me when I do stop and think about what could happen. So let me say again that I think it is a good idea to have a copilot stand next to you while you are in flight, not only for the safety of you and your plane, but all the other pilots and spectators at the field.

|

New Planes

Jody Gann's New Chipmunk

|

Wayne Long's Airmadillo

|

Wayne Long's Giles

|

Recent E-mail

Can you please... I'm begging you.. (this is bad a grown man begging LOL ) please give me a little info on two of your planes.. the spinsation and the fat boy...

I'm prepared to offer you my girlfriend and her house along with the car and her bank account for those two planes...

MY GOD you have the Kewlest planes.. I can't beleive it. I've been sending your link to everyone here in Niagara Falls Canada to check it out. The fat boy is the first I want to build and then the spinsation... How do they fly?

Any plans you want to sell? Man you the King.. I know it's pretty bad that I'm drewlling over your planes but man I love it... If you are interested I have this plane I'll part.. 1/5 scale bonanza we can make a deal if your intersted..... L8ER Randy

Reply

Good to hear from someone in Canada! Sorry it took so long to reply back, but I have a home remodeling project going on and haven't seen my computer for a while. That is a nice looking plane you have, I bet it does some goon maneuvers. The Spinsation is a really good plane for wild aerobatics. I have been flying it for about four or five years now and it is still one of my favorites. It has some moves that no other plane will do. The Fat Boy needs more power up front, I am replacing the .91 OS four stroke with a Saito 1.80. I know this sounds extreme, but that 6 inch thick wing needs the power. The .91 just did get it off the ground and was tail heavy so it needs the weight up front. I think it will fly great with more power. I don't really want to part with any of my planes at this time, I just like having them around. When I get some free time I can give you more info on them if you like. Thanks for looking over my web site Randy and keep in touch. James

|

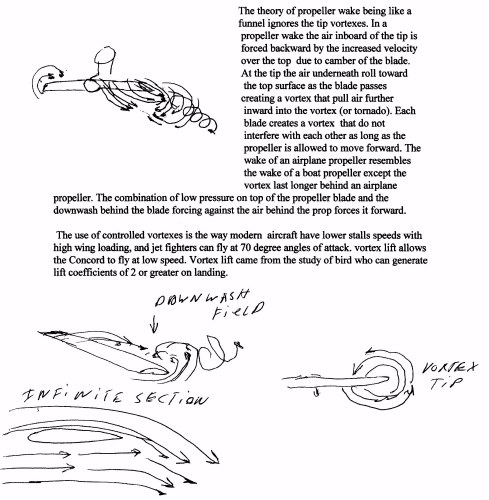

Propeller Wake

By Jerry McCuistion

|

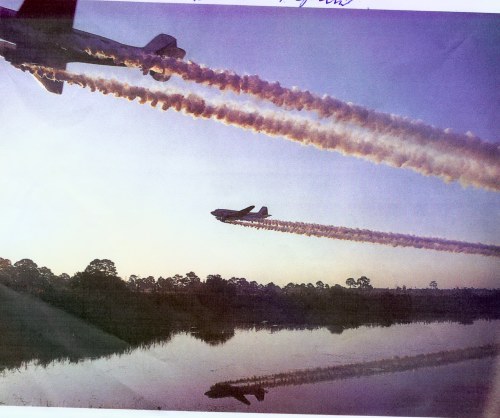

Here in Ken's photo you can see the spiraling propeller wake.

|

Joe Nall 2002

By Dr. Vic Cestaro

Full size Cap 232

Notice the On-Off switch

|

|

This is what I call a flight line!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|